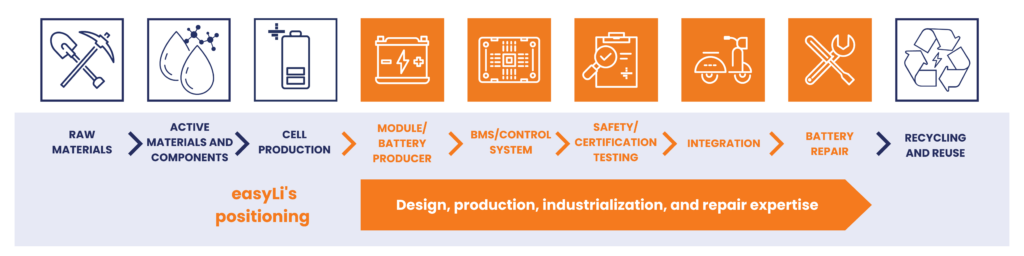

From the mining of raw materials to your vehicle’s battery, there are many and intermediaries. easyLi focuses its expertise on battery systems. Discover easyLi’s position on the battery value chain and its added value thanks to the multitude of integrated processes involved in designing your batteries.

Raw materials mining, refining and components

Raw materials are mined in different countries, depending on the raw materials needed to manufacture the different battery technologies. For example, for lithium (easyLi’s expert technology), 90% of the materials extracted come from Australia, Chile and China. This extraction phase can pose social and environmental issues. For lithium, unlike cobalt, the difficulty is mainly environmental before being social. In the case of the Andean salars, lithium carbonate is extracted by water evaporation, which can pose problems for agriculture and other uses in dry areas.

When it comes to refining raw materials, China has a monopoly. Refineries, mainly located in China, buy raw ores, purify them and transform them into added value products: lithium hydroxide, lithium carbonate, cobalt sulfate… From these active materials, battery cell components manufacturers mix them with certain additives to produce the active materials that make up battery electrodes. The purity of the materials used and the nature of the additives determine the performance of the final cell. This is why the major cell manufacturers have chosen to internalize the chemical formulation of their products.

From components to batterry cells

The manufacture of cells for battery systems, especially for electric vehicles, is a business still dominated by Asia, but which has a tendancy to develop in Europe. Indeed, since the release of the Commission’s report to the European Parliament in April 2019 – Implementing the strategic action plan on batteries: creating a strategic battery value chain in Europe – the dependence of the European battery industry on non-European players has been clearly identified. Since then, gigafactories have been multiplying in Europe. At the same time, to maintain access to its domestic market, and attempt to counter Asian hegemony, The European Battery Alliance (was created in 2017.

The Battery System, easyLi's core business

As a French expert in designing and manufacturing custom batteries, we help you define your battery system, from designing the mechanics, electronics, and the associated BMS (Battery Management System) to characterizing the individual cells, performing 100% quality control and safety tests, and assisting you with certification procedures.

We hold direct supply chain relationships – no distributors – with our component suppliers, and we manufacture your batteries in our workshops in France.

We advise you on how to integrate our battery into your devices and vehicles and share our expertise regarding charging infrastructure implementation rules if you manage a fleet of vehicles. We also continue to provide you with support via our MRO (Maintenance in Repair Overhaul) services to ensure you can use your batteries in the long term as we integrate our #DesignForRepair approach from the outset of the design stage.

To be repaired, your battery has to be repairable!

Eco-design is the key to its reparability, and must anticipate ease of dismantling, inspection and replacement of components, BMS, cells… This is an important consideration right from the specification stage, in the quest for the smallest possible environmental footprint.

A picture is worth a thousand words: the Battery value chain

The battery value chain includes various players with specific expertise. Here is a representation of our strategic positioning on this value chain.

Let's keep in touch

Do you have a project? Do you need some information? Would you like to know more about our long-lasting lithium battery solutions?